SUSTAINABILITY AND THE SCIENCE OF WELL-BEING

Download the Program at a Glance

Monday, November 18, 2019

10:00 am 2:45 pm

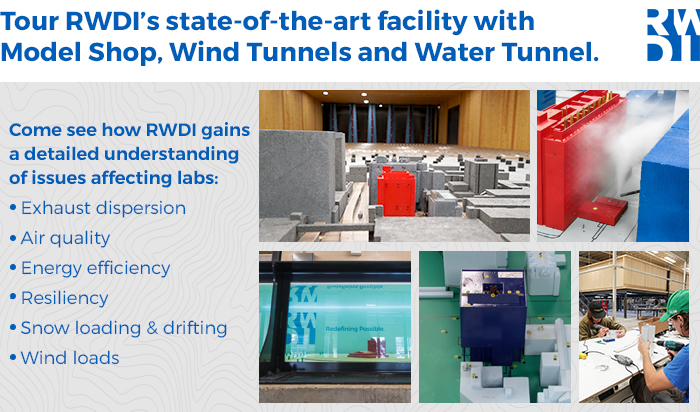

RWDI Facility Tour

5:00 pm - 8:00 pm

Networking Reception in the Trade Show Area

Tuesday, November 19, 2019

Stream 1

Design & Engineering

Stream 2

Operations and Facilities Management

Stream 3

Products, Technology and Energy Management

7:30 am – 8: 15 am

Continental Breakfast in the Trade Show Area

8:15 am – 8:30 am

Welcoming Remarks

8:30 am – 9:00 am

Keynote

WELL 101: Introduction to the WELL Building Standard

View Video

Sandra Dedesko, RWDI

Sandra specializes in high-performance buildings that promote occupant health and environmental sustainability. She has international research and consulting experience in this area, and brings this multi-dimensional perspective to all roles. She was previously involved in academic research that examined the impacts of building design and operation on indoor environments and occupant health, and is now applying these findings to projects through her current role as a Sustainability Consultant at RWDI. Sandra has and continues to be involved with developing and delivering education through the University of Toronto, the CaGBC, and the IWBI.

Description

The WELL Building Standard has emerged as the leading rating system to address indoor environmental quality and occupant health, wellbeing, and productivity in the built environment. As WELL is still fairly new to the industry, not all building professionals and sustainability practitioners are familiar with the related background, concepts, structure, process, and benefits. With respect to laboratory spaces specifically, there are only a handful currently participating in the WELL Building Standard (i.e., registered and/or certified), which provides an exciting opportunity for leaders in the sustainable laboratory design and operation field to pursue this occupant-focused building certification.

This introductory session to WELL begins with a motivation for indoor environmental quality and health in buildings from both a financial and occupant wellbeing perspective. Next, the WELL certification process is introduced, including a discussion of WELL’s differentiating components, which include on-site performance testing and re-certification requirements. Following this, the structure of both WELL version 1 and the WELL version 2 pilot are presented, with an overview of the concepts, features, and requirements in each. pes and operating practices (i.e., healthcare facilities).

9:00 am – 10:00 am

Panel Discussion

Sustainability and the Science of “Well-being”

Moderator

Steven Ploeger, DIALOG

Steven Ploeger is an architect and associate at DIALOG, leading the firm’s laboratory and science planning for the Toronto studio. He brings 30-years of industry experience to the sustainable development of innovative projects in the fields of public and private sector research, academic research and teaching labs, healthcare, pharmaceutical production facilities, biotechnology and forensics, and law enforcement. Steven is a member of RAIC, a LEED accredited professional and is a member of the International Society of Pharmaceutical Engineers (ISPE), the Society for College and University Planning (SCUP), and Sustainable Labs Canada.

Panelists

Antonio Gomez-Palacio, Principal, DIALOG

Antonio Gomez-Palacio is a founding partner of DIALOG. He is internationally recognized for transforming cities into vibrant urban places. His work spans a wide range of projects focused on urban intensification, master planning, mixed-use, transit, heritage, economic development, and sustainability. Antonio has acted as the Chair of the Toronto Society of Architects and Vaughan’s Design Review Panel and is involved with industry initiatives and organizations including the Canadian Institute of Planners, the Royal Architectural Institute of Canada (of which he was named a Fellow in 2018), and the Canadian Urban Transit Association. He is currently leading multi-sectoral research on the link between built environments and community wellbeing.

Sandra Dedesko, Sustainability Consultant, RWDI

Sandra is a sustainability consultant at RWDI. Her focus is on high-performing buildings that are healthy and sustainable. She has international consulting experience including LEED and WELL, and NABERS in Australia and Asia. Sandra also has extensive experience in academic research and was involved with the US Department of Housing and Urban Development’s Healthy Homes research initiative through the University of Texas at Austin, and the Alfred P. Sloan Foundation’s Microbiology of the Built Environment projects through the University of Toronto. These projects involved novel approaches to investigating the effects of building design and operation on indoor environmental quality and occupant health and wellbeing. Sandra has presented at multiple international conferences and meetings and has produced several peer reviewed publications on this topic.

Ian McDermott, Senior Director, Research Facilities Planning and Safety, University Health Network

Ian McDermott is the Head of Planning & Integration (capital planning) and the Senior Director of Research Facilities at the University Health Network (www.UHN.ca) in Toronto, Ontario, Canada. He is also is the Past-President of Sustainable Labs Canada (www.SLCan.ca). Ian has been a member of the Senior Management Team for Research at the University Health Network for the last 21 years and was a member of the Research Management Team at the Wellesley Hospital Research Institute since its inception in the early 1990s until 1997. In his current roles he works intimately with clinicians, researchers, administrators, engineers, architects, contractors, building operators, vendors and regulators in designing laboratories and establishing operational parameters. Ian and his team are scientific and space interpreters, translating needs and concepts between the users and design/operational teams. He is also responsible for the Facility Maintenance and Operations of both the Princess Margaret Cancer Research Tower (MaRS) and the Krembil Discovery Tower. Ian strives to ensure these environments continue to be leading sustainable research environments meeting the needs of the UHN Researchers. With a clear focus on the needs for patient care, research and education, Ian has been instrumental in developing effective, efficient and safe environments that are sustainable while continuing to meet all the regulatory guidelines. Ian holds a Specialist Degree in Molecular Genetics and Molecular Biology from the University of Toronto.

Todd Coulter, Director - Facility and Property Management, Public Health Agency of Canada

BIO coming soon

Kevin Humeniuk, National Sector Leader, Science & Technology, Architecture 49 Inc.

Kevin is a design architect, having obtained his Masters Degree in Architecture from the University of Manitoba in 2000. He is a registered member a variety of provincial architectural associations, as well as the Royal Architectural Institute of Canada. Kevin is a proud board member for Sustainable Labs Canada, and is a LEED Accredited Professional. Over his fourteen years in architectural practice, Kevin has gained considerable experience in a wide variety of roles and responsibilities. He has been a project manager and design team member responsible for client liaison, functional programming, laboratory planning, and architectural production work on a variety of science projects. For the past ten years, Kevin has been exclusively involved in research laboratory projects as a project manager, project architect and laboratory planner.

Kevin has presented at various conferences and seminars, including at Tradelines, the RPIC Real Property National Workshop, and the Canadian Biosafety Symposium.

Description

Join us for what we anticipate will be a thoughtful and engaging discussion on the concept of well-being, and how we can effectively and meaningfully integrate the concepts of well-being into our work in the sciences and sustainability. With a continued focus on the occupants and their day-to-day experiences, our panel will explore the tools and techniques of well-being that result in comfortable, healthy and happy occupants. We have assembled a diverse panel of experience in planning, design, consulting and facilities planning and management that will bring a unique perspective to the challenge:

“How do we take care of our people - How do we create people places that enhance the experience, enjoyment and productivity of the Users of those spaces?”

10:00 am – 10:30 am

Refreshment Break in the Trade Show Area

10:30 am – 11:00 am

Keynote – Speaker

Update on I2SL

View Video

Phil J Wirdzek, International Institute for Sustainable Laboratories

Phil Wirdzek is the founding president and executive director of the International Institute for Sustainable Laboratories (I2SL(r)). His areas of expertise include environmental risk assessment, industrial microbiology, wastewater systems, facility management, energy efficiency and sustainable environmental policy. He served as chair of Carnegie Mellon University’s Center for Advanced Building Systems Integration and Diagnostics for more than a decade and is presently adjunct faculty in the Sea Grant Institute at the University of Hawaii, Manoa HI. Mr. Wirdzek has received numerous awards, is a frequent speaker at many national and international events, and has been published in various trade journals.

Description

As I2SL approaches its 20th year of operations, the organization continues to globally promote its mission and ensure the development of tools that may be useful to the lab community. Since 2019, I2SL has gained a chapter in Mumbai, India, to join those in China and Singapore. I2SL is also engaged with a group in Australia to establish a chapter in that country. In terms of tools, I2SL just launched the Laboratory Benchmarking Tool (LBT) which replaces the retired Labs21 benchmarking tool. Included with the LBT is a unique module called the Actionable Insights module to enable owners to consider opportunities and strategies for energy efficiency. I2SL is also supporting several working groups addressing lab waste reduction, recycling for lab plastic and styrofoam packaging, laboratory ventilation effectives, and the development of an owner’s manual for laboratories. All of these groups either met or reported progress at the 2019 I2SL conference. Finally, I2SL is planning to continue the ‘Lab of the Year’ recognition program and expects to announce its plan in 2020.

11:00 am – 11:30 am

Keynote Presentation

WELL Lab Building Adoption – “Better Environments - Supporting Your Core Research Mission”

Dan Diehl, Aircuity Inc

Dan brings over twenty-five years of industry expertise across a wide variety of vertical markets and disciplines in commercial and light industrial building markets. Prior to Aircuity Dan led business development at Lutron Electronics, was a partner for six years with Synergy and spent 11 years at Johnson Controls, Inc. Mr. Diehl earned a BS degree in Mechanical Engineering from the University of Maryland and has an MBA from Villanova University.

Description

Recent studies have proven that a better indoor environment can lead to improved cognitive ability- something that is extremely important when it comes to a research facility. The WELL Building Standard is comprised of 100 features that are all designed to address issues that impact health, comfort and knowledge of occupants through building design, operations and human behavior. A WELL Certified building helps attract and retain top talent in laboratories and adjacent areas. Multi-parameter demand control ventilation helps earn points towards features WELL’s Air category while also reducing energy and positively impacting cognitive function of lab occupants. This presentation will provide a brief overview of WELL, review the features that MpDCV can affect and explain the benefits of having a “WELL Ready” research facility even if a WELL Building Certification isn’t immediately pursued.

11:30 am - 12:30

Concurrent Sessions

Stream 1

Slashing Vivarium Energy Use With the Newly Issued CCAC Guidelines on Air Quality Monitoring & Control

Gordon Sharp, Aircuity Inc.

Gordon Sharp is the chairman of Aircuity and has over 25 years of experience and over 25 patents in energy efficiency, indoor environmental quality, and laboratory controls. Before founding Aircuity in 2000, he was the founder

and former CEO of Phoenix Controls.

Gordon is an MIT graduate, an ASHRAE Distinguished Lecturer, and the Executive Vice president and a member of the Board of Directors of I2SL. He is also a voting member of ASHRAE Standard 170 on Healthcare Ventilation and the ANSI Standard Z9.5 on Laboratory Ventilation as well as a member of the ASHRAE TC9.10 committee on Laboratories.

Description

The largest source of a vivarium’s energy consumption and carbon emissions is the significant use of outside air to provide high air changes per hour (ACH) dilution ventilation. In the past, a prescriptive approach to ventilation in the form of a requirement of 15 to 20 ACH was a part of the CCAC guidelines making it difficult to significantly reduce the energy use in these facilities, at least in Canada. However, changes have now been made made to the CCAC guidelines in the form of a recently issued addenda that allows significant reductions in vivarium ventilation rates, and thus energy use, through the use of real time vivarium air quality monitoring and airflow control. This webinar will detail this performance based CCAC addenda and the specific approaches and requirements it lays out to reduce vivarium airflow rates as well as the air quality parameters that need to be measured and the air quality levels that need to be maintained to provide clean air conditions in a vivarium. This talk will also review one example of a technology approach that meets the new CCAC requirements in a cost-effective manner to provide significant energy savings. Some quantitative case studies of past US projects and a sample ROI analysis will also be presented.

Stream 2

Special Application Fume Hoods: What Are They and Do We Need Them?

Deni Antonecchia, Preston Phipps Inc.

Deni Antonecchia is a mechanical engineer and a member of the Québec Order of Engineers having obtained his undergraduate Mechanical Engineering degree from Concordia University (Montreal, QC) as well as his graduate diploma in Management from McGill University (Montreal, QC)

As newly appointed Executive Vice-President for Institutional Sales at Preston Phipps Inc., Deni leads and supports the entire sales team from coast-to-coast and is responsible for all projects and product offerings for the Canadian institutional market.

Deni has been involved in the laboratory market since 2005. With significant experience in critical air applications and HVAC systems, his expertise now includes lab environment functionality, more specifically with regards to fume hoods and casework. With this, he has been involved is several high-profile lab projects across the country and continues to lend his expertise in designing the “labs of tomorrow” with a sustainable approach in mind. Since 2015, he has also been an active member of Sustainable Labs Canada, particularly as the administrator for the Montreal Chapter.

Outside of the “Lab World”, Deni is knowledgeable in HVAC and piping systems, more particularly when it comes to critical air systems, steam/condensate management and hydronic loops. With 15 years of experience in the field, he can troubleshoot, design and provide aid when it comes to numerous thermodynamic and heat transfer applications. Deni is also a vital contributor to Preston Phipps’ accredited Steam and Laboratory Seminars by continuing to play a key role in developing the course content and by participating as a presenter.

Description

Are the right types of fume hoods being used for the variety of experiments performed or the type of instruments being used or even the reagents being manipulated? Do we even know what is “going on” in our fume hoods? This needs to be thoroughly assessed and properly understood if we are to promote SAFETY and the WELL-BEING of personnel in our Canadian lab environments.

For many years now, our European colleagues have adopted an interesting approach, using adequate types of fume hood based on the application(s) at hand. The EN 14175 standard clearly defines the necessity and requirements for “Special Application” fume hoods. This approach is seldomly considered in Canada as our standards and guidelines do not accurately address this important topic. The European lab design requirements do.

The requirement of a fume hood to have the proper air flow pattern (fluid and thermodynamics) combined with the right selection of materials and its cleanability, are at the basis of the European philosophy.

One cannot assume that general-purpose fume hoods are the right solution for all applications. This approach is not applied to Bio Safety Cabinets, so why do we assume it for fume hoods? If we are to generalize and assume that all applications are the same, then how can we ensure and promote safety? We are fooling ourselves if we believe that such an approach is just.

So, is this the reason why we have a tendency to prescribe such high flow rates for general-purpose fume hoods without adequately testing them? We must also ask ourselves if the proper containment testing procedures are being used and which guidelines or resources are available? Not a simple task…

With multiple fume hood designs available today, we could now asses what is required and validate which type of hood to use for the application.

This and other related topics are to be discussed in this during this presentation.

Stream 3

Labs of the Future: How do You Select Materials to Meet Sustainability and a Reduction in Carbon Footprint.

Dawn Jacobs, American Epoxy Scientific.

TBD

Description

Collaboration; Flexibility; Sustainable; Net Zero; Carbon Footprint;

All key buzzwords that are utilized in everyday discussions when considering new builds and refurbishing laboratories. But what do they really mean and how do they really impact the way labs are planned, designed, built and of course used? Or is it just marketing hype with no real time benefits to the user?

This paper will cover brief explanations to the meanings of each 5 key topics and how selecting materials to ensure the requisites of carbon neutrality and sustainability are met.

Following on from the summary explanations, we will then take a closer look at cross section of projects that are currently being planned, implemented or recently built – with the thoughts of flexibility, collaboration, sustainability etc in mind.

These projects will be highlighted from a manufacturing perspective, taking a closer look at how it is incumbent upon us as an industry to help ensure those requirements are met and exceeded. Therefore, how can lab planners, architects and users be sure the materials selected meet the sustainability issue without deviating from its core purpose? How should the industry be helping drive change?

Our presentation will then conclude with an overview on how industry can help drive and not hinder the progression towards more sustainable, flexible and net zero workspaces.

12:30 pm – 1:30 pm

Lunch and Keynote

Outlook on Some Promising Technologies on the Path to Building Decarbonisation

Frederic Genest, Natural Resources Canada / CanmetENERGY

Bio to come

Description

Whether they be carbon neutral portfolio plans, generic decarbonization studies or specific energy/carbon audits, recent publications on the topic of reducing greenhouse gas emissions from buildings identify key strategies to reach that goal. Among them, the electrification of heating (notably with the use of heat pumps) and smart buildings controls figure prominently. Replacement of the refrigerant gases that have a strong global warming potential (GWP) is also receiving a keen interest.

This presentation aims at introducing the audience to some recent technological advancements which are among the research topics of the Buildings Group at the CanmetENERGY Research Centre in Varennes. More specifically, the talk will focus on the following topics:

- Model predictive controls, where a simplified building energy model is tied to weather forecasts in order to optimize the operation of building systems; the presentation will summarize the principles and present results from the implementation of the control sequences into some candidate buildings.

- CO2 refrigeration and heat pump applications, summarizing the current product lineup of CO2-using refrigeration equipment and presenting operational results from a prototype direct-expansion geothermal CO2 heat pump installed at the Varennes Centre.

- Standing column wells, which is an open-loop variant to the typical vertical ground-coupled geothermal heat exchanger; the presentation will describe the technology and expectations related to operation and performance.

1:30 pm – 2:30 pm

Concurrent Sessions

Stream 1

CBS- Building the Optimal Environment-Balancing Design and Process

Frank Panici , NORR Architects & Engineers ltd.

Frank Panici is the Vice President of NORR. He values building client relationships and believes the in the value of design in creating health and wellness within our projects. Combining his creative and technical skills, he seeks to achieve optimal building solutions for his clients. Projects like The Canadian Blood Services and The Science Research and Innovation Facility at the University of Windsor is one of Frank’s latest clients, demonstrating that NORR’s health science experience goes well beyond hospitals.

Frank’s expertise does cross into many other sectors and he counts Canadian Blood Services Calgary Distribution and Processing Centre along with The Science Research and Innovation Facility at the University of Windsor, Peter Gilgan Patient Care Tower at St. Michael’s Hospital, Princess Margret Cancer Centre Space Transformation and the 2015 Pan Am Aquatics Centre and Field House among his favorites. But connecting with more health sciences professionals is our goal.

Chris Pal, NORR Architects & Engineers Ltd.

Bio to come

Description

The CBS project is designed as a bold gesture: a transparent facade that wraps around the central processing facility – reflecting an open and transparent process that fosters collaboration, integrity and respect. The transparent facade is anchored by a stone entrance contrasting the glass massing of the building allowing light and nature to engage with its occupants. The form and materiality of this bold gesture will make tangible the optimism and confidence and excellence in delivering service. We will show through a case study of the finished building how this project was designed for the people and of the people showing examples, design initiatives, user process that achieved a significant building for the Canadian Blood Services.

Learning Objectives

Learn, explore, obtain, describe, etc.

1. Explore the design challenges that come with designing a laboratory space to best practices and GMP processes.

-We will walk through the entire design process from site selection to detailed layouts of both the processing area and the administration area. We will review design objectives and client requirements and how our design responded to the clients requests

2. Learn about how our design creates a quality of Space building on WELL design principles.

– The importance of light and transparency will be discussed and reviewed. We will detail how the design responds to the users and how our design enhances to user experience. We will review WELL Design Principles and how they applied to the building.

3. Gain in-depth insight into 2 case studies focusing on the Laboratory / Processing component and the Social/ Administrative component of the building.

– Reviewing the building as a whole will lead to the socialized areas of the facilities. We will review the exacting requirements and standardization in process within the Processing area and also run through the social aspects of the building, its site and the surrounding environment.

Stream 2

Energy Management in Critical Environment

Abiola Adebayo, Black & McDonald

Abiola Adebayo is an Energy & Sustainability Project Manager with Black& McDonald. His academic and professional experience ranges from Building energy management, automation and control to modelling distributed energy resources in both vertically integrated utility system as well as deregulated electricity market.

Abiola works as Energy Manager for P3 complex facilities in multiple jurisdictions with primary responsibility of optimizing energy consumption and cost, while maintaining strict indoor air quality and reliability standards. His role also involves applying distributed energy resources (DER) to offset facilities’ peak energy consumption to reduce energy cost and also support the grid through demand response.

Description

Over the years, energy component of P3 contracts have become more and more stringent. As they usually are performance contract-pain/gain share, Energy Manager within this framework has to always be in constant pursuit of opportunities to reduce energy usage without compromising space requirement. Implementing energy conservation measures requires detailed review of existing design to establish the rationale behind certain specifications and seeking opportunities to fine-tune them so as to optimize energy consumption.

In this presentation, we will be sharing our experience on little to no cost approach we used in improving the performance of the P3 Health care facilities we run. Our presentation would cover all the conservation measures we implemented ranging from fine-tuning the heat recovery mechanism and low pressure steam humidifier performance to chiller sequencing. We will also cover measurement and verification of the savings achieved from the implementation.

Also, we plan to share our approach in persuading key stakeholders involved to allow testing implementation of ideas could result in energy savings.

Stream 3

Net Zero Labs – An Achievable and Cost Neutral Approach

Kevin Belusa, AirGenuity Inc.

Kevin Belusa, B.Sc. President of AirGenuity, focuses on Government, University and Health Care applications and has an extensive understanding of owner requirements for their built environment. Kevin specializes in providing green solutions to owners, engineers & architects to reduce the energy profile and carbon footprint of the critical spaces within the built environment.

Kevin has a Bachelor of Science Degree from the University of Toronto in Physics and Math. He is also a proud founding Vice President of Sustainable Labs Canada (SLCan), Founding president of the Toronto Chapter and holds a position in a number or SLCan Committees.

Description

As Canada moves towards a carbon neutral and net zero model for all buildings, a new method of evaluating critical design elements needs to be developed which incorporates the synergistic impact of the adopted technologies. HVAC design and the associated technologies must be viewed as a whole and not as individual contributors towards our goal of energy reduction. This presentation will provide a frame work for owners, engineers and architects to be able to understand and evaluate various technologies and the impact they will have on the their entire HVAC system. When applied correctly the content of this presentation will allow for capital cost neutral or cost reduced facilities in medium to large renovations as well as new construction. A case study will be provided to illustrate the applicability in one of the worst possible climates for Net-Zero.

2:30 pm – 3:30 pm

Concurrent Sessions

Stream 1

Pre-Design in Laboratory Renovation: The Critical Step to Sustainable, Contemporary Lab Solutions

Drew Hauser, McCallumSather

Drew is a registered OAA and AIA architect passionate about shaping science & research, health care and post-secondary environments that put our clients’ objectives at the forefront. He has been instrumental in providing award-winning design solutions with a specific focus on design for a range of medical, animal, laboratory and research typologies. This is combined with a unique background in renovation and forward thinking health care projects, experience with animal health care environments including the unique requirements of these sensitive patients, and a strong history working on complex and fast-tracked projects of all complexity. He recently completed his Laboratory Design and Safety training certificate at Harvard University, is a member of the Scientific and Equipment and Furniture Association and participated in the Laboratory Design Conference in Philadelphia earlier this year. Drew’s understanding of renovation projects is complemented with his Canadian Association of Heritage Professional Accreditation.

Mary Georgious, McCallumSather

As a LEED BD+C certified designer, Mary’s designs are informed by sustainable approaches, focused on how to advance social, economic and environmentally sustainable solutions. Mary’s resume includes a wide variety of projects, including industrial, institutional, healthcare and commercial projects. She is well informed of all codes and standards in the building design field and remains forward-thinking in the integration of new technologies, to ensure the best possible outcome on our clients’ behalf. An enthusiastic leader, Mary offers extensive experience in HVAC, fire protection, plumbing and medical gas system design. As the firm’s mechanical engineering lead, Mary’s strength is in project management and problem solving, ensuring all mechanical solutions seamlessly integrate into a project’s design.

Description

How does high-quality, contemporary laboratory design fit within a renovation context? As a multi-disciplinary team including Architects, Mechanical Engineers, and Lab Specialists based in Canada, we share our expertise of the value of pre-design and how it relates to standardization of complex user requirements in order to achieve project goals.

Explore the role of the Pre-Design process in sustainable renovations of complex laboratory design, including practical tips on how to use this process to structure the client’s investment, standardize laboratory layouts while still responding complex user requirements and to achieve advanced sustainability objectives.

Stream 2

Sustainable Transitions in the Laboratory Space – The Incorporation of IoT Technology

Kelly Christensen, Black & McDonald

Kelly Christensen is a Project Manager on the Energy and Sustainability team at Black & McDonald. Kelly is responsible for identifying, consulting and managing projects for Black & McDonald clients in regards to their sustainability initiatives, including energy, water and waste aspects of programming at facilities. The majority of Kelly’s efforts include contributions in critical environments, including laboratories, museums and art galleries. Kelly holds particular interests in building efficiency through big data and IoT technology and is a strong believer in the application of IT innovation in the world of operational technology in finding solutions that satisfy requirements of both efficiency and finance. Kelly is LEED accredited professional and holds a Bachelor’s degree in Honours Health Sciences from the University of Ottawa and a Master’s degree in Sustainable Energy from Carleton University.

Description

The objective of this presentation is to share best practices and learnings regarding incorporating technology into laboratories where normal energy conservation measures present a challenge due to the facilities stringent climatic requirements. The value of utilizing IoT technology such as submeters and energy management dashboards in these facility types will be highlighted, as will the energy conservation measures which were discovered and implemented through this work at Krembil Discovery Tower. The environmental impact, as well as the operational impact will be discussed.

Stream 3

Energy Saving Through Exhaust Stack Discharge Volume Reduction (ESDVR)

Douglas Ross, M.K. Plastics

Doug Ross is an Automation and Control Engineer from the Auckland Technical Institute in New Zealand. Doug successfully completed turnkey automation projects for companies such as Ford Motor Company New Zealand, Fisher & Paykel Healthcare and BHP New Zealand Steel.

In 2013 Doug joined M.K. Plastics Corporation as the Canadian Sales Manager; working with the Canadian Sales Representatives with commercial, institutional and infrastructure applications, where corrosive elements are present. In this period Doug also established a new Australasian Sales Representative and presented a paper at the Australian Laboratory Managers Conference in 2014 outlining the benefits of manifold laboratory exhaust systems compared too individual ducted systems.

Doug has worked on Laboratory exhaust system designs, both in Canada, USA and Australia. Doug has a particular interest in the total system approach to designing economically viable and sustainable exhaust systems for critical environment applications.

Description

A laboratory ventilation system can be broken down into three parts: the fresh air supply, the conditioning components (e.g., temperature, humidity, and filtration), and the exhaust system. The fresh air supply and conditioning systems account for approximately 60% of the ventilation system energy consumption and have been the focus of laboratory designers for the last several decades.

Unfortunately, energy-saving opportunities for the exhaust system are often overlooked, even though these systems account for the remaining 40% of the ventilation system’s energy consumption (and about 30% of the laboratory building’s total energy consumption). This presentation examines a strategy that can safely reduce the exhaust system’s energy consumption by at least 50%.

3:30 pm – 4:00 pm

Refreshment Break in the Trade Show Area

4:00 pm – 5:00 pm

Concurrent Sessions

Stream 1

Innovative Sustainable Laboratory-University of Windsor SRIF

Frank Panici, NORR Architects & Engineers

Frank i is a Vicepresident at NORR with over 25 years’ experience, and currently leads all the Biotechnology and Health Sciences projects. Frank is experienced in all sectors including institutional, industrial and commercial. He has worked on many health care projects in laboratory and health care facilities that vary in size and complexity. Frank has developed successful relationships with multiple Healthcare institutions across Canada and the US.

Doron Meinhard, Hariri Pontarini Architects

Doron is an Associate Partner at Hariri Pontarini Architects with 20 years of experience in multiple

large scale projects nation wide. Doron brings in leadership, a full understanding on how complex buildings function and how every component should be detailed and integrated into outstanding Design concepts.

Memo Terres, NORR Architects & Engineers

Memo is a Project Manager at NORR with 17 years of experience, who has lead multiple Healthcare/ Laboratory projects, Sports venues, Commercial, Residential and Transportation facilities which have been built worldwide. Memo is a hands on technical expert, team leader who supervises the implementation of project specific solutions, while managing clients and the financial aspects of projects, in order to ensure successful outcomes.

Description

The University of Windsor Science Research and Innovation Facility project is a new three storey building which became operational in late 2018. NORR and HPA worked closely with the Users to understand their day to day experiments, procedures and needs. While developing a consistent design, we implemented specific Laboratory bench configurations, base cabinetry, services, materials and space allocations in order to customize each Lab to the Users’ needs. At the Design meetings, the Professors and specialists would review their portion of the space and we would guide them into achievable solutions which worked with the overall design. Concepts such as: natural light, high ceilings, open/ integrated Labs, accessibility, safety (duct welding), wood elements at common areas, Energy efficiency, durability and intuitive wayfinding were all addressed and incorporated into the design, which have resulted in an optimized experience.

At the end of our presentation, we will connect the concepts described above to the most relevant WELL/ Sustainable principles such as: Evidence Based, Resilient, Customer focused and Technically robust design, and how these can successfully be integrated to specific technical requirement of future Laboratory projects in order to enhance their habitability, which will surely result in a higher productivity and results.

Stream 2

Characterizing Risk and Future Flexibility in Laboratory Exhaust Design

Ruth McMath, RWDI

Ruth is an experienced air quality specialist who specializes in wind tunnel and numerical modeling to study exhaust dispersion challenges for new and existing buildings. In her work on institutional, healthcare, and private laboratories, Ruth combines expertise in microclimates and exhaust dispersion with practical insights to support and optimize clients’ laboratory performance objectives.

Description

According to WELL v2, “the WELL Air concept aims to ensure high levels of indoor air quality across a building’s lifetime through diverse strategies that include source elimination or reduction, active and passive building design and operation strategies and human behavior interventions.”

This presentation explores how this concept can be used to guide a definition of “acceptability” for a mechanical laboratory ventilation system. Safe dispersion of exhaust with potentially high chemical concentrations is often referred to in the context of meeting occupational health-based exposure criteria, but this approach may fail to account for other detractors from air quality such as odours, or long-term exposure. Additionally, these criteria vary widely for different chemicals. Ultimately, achieving safe, effective, and energy-efficient dispersion of laboratory exhausts involves a broad array of considerations, all of which can impact the wellness of laboratory users, and the flexibility of the laboratory to accommodate changes in use over its lifespan. Designing a highly robust exhaust system provides more flexibility, but can come at a high cost in terms of energy and aesthetics. Conversely, a system that is highly energy efficient may put significant onus on human behaviour interventions to ensure controls are used effectively and protocols adhered to.

This presentation will explore the challenges of characterizing risk from laboratory activities, how these risks influence the potential for energy use reduction, and how these issues can potentially be overcome without over-designing exhaust systems. By developing a better understanding of the types and intensity of chemical use, along with the wellness of the laboratory users and neighbouring populations, more information becomes available on the applicability of various benchmarks for achieving “good” dispersion of the exhaust. Three theoretical case studies will be presented to illustrate these concepts: a research-intensive clean room, an undergraduate teaching laboratory, and a small diagnostics laboratory tenant in a multi-use urban building. Participants will be guided through key aspects of each case study that illustrate different control strategies and the trade-offs between efficiency, flexibility, and cost with respect to the laboratory exhaust system design while ensuring the wellness of laboratory users and their neighbours.

Stream 3

Implementing Intelligent Infrastructure to Deliver Safe, Energy Efficient Labs That Appeal to Generation Z

Paul Fuson, Siemens Smart Infrastructure

In his current position, Paul manages sales and business development efforts focused on Life Science and Laboratory markets in 100+ offices across North America. He holds an MBA, a BS in Mechanical Engineering and a BS in Physics. With more than 35 years experience in the building controls industry, Paul has spent the past 30 years developing & delivering safe and effective ventilation control solutions for critical environments. As Product Manager, he developed Siemens venturi air valves, retrofit kits for competitors’ systems, lab blade damper terminals, pressurized room and fume hood control, lab Demand Control Ventilation and other components of the Green Lab Solution. Paul is a frequent speaker and participant with ASHRAE, ASHE and I2SL.

Description

As more than 61 million Gen Zers will make up approximately one-fifth of the workforce by 2021, the pressure is on for labs to transform their outdated spaces into the future labs of tomorrow. Unfortunately, many of today’s labs continue to rely on outdated practices.

Attendees of this session will learn how IoT-based methodologies can intelligently combine the control and management of heating, cooling, ventilation, containment, lighting, and daylighting into a single platform to provide greater occupant comfort, workspace flexibility, and lab safety and performance. Monitoring and assessing data analytics for labs provides visibility into performance, thereby optimizing operations, reducing downtime, and contributing to safety and compliance efforts and a reduction in energy consumption.

Key Takeaways:

> Identify the variety of ways that current and future scientists’ and lab workers’ activities and policies influence energy consumption in a facility.

> Recognize different aspects of room infrastructure, HVAC, lighting, and daylighting and review the latest technologies for their control and management.

> Show how the Intelligent Infrastructure supports compliance with WELL standards and improves the experience for building occupants.

> Walk through examples of using new technologies, and new ways of using old technologies, to improve interaction of lab occupants and building systems to deliver safe and efficient buildings.

> Learn how analytic services for labs can provide a systematic, preventive maintenance approach for lab ventilation and sash management.

> Understand how to use data specifically to identify the critical fume hoods and lab spaces that require continuous monitoring.

> How lab managers can gain lab transparency, visibility and guidance for lab optimization strategies, equipment maintenance, and services to improve lab performance.

5:30 pm

Evening Event

Ripley's Aquarium

This years stand-up dinner event will be held at Ripley’s Aquarium of Canada, in Toronto. It is a 135,000 square-foot incredible attraction with more than 1.5 million gallons of water with marine and freshwater habitats from around the world.

The Stand-up Dinner Event will be held in the Dangerous Lagoon Overlook and Behind the Scenes Tours have been arranged. Tours will showcase the inner workings of the aquarium, where animals are cared for. You will travel on moving glide paths, and come face to face with thousands of fascinating fish and menacing sea creatures - everything from barracudas, to rays, to jellyfish, octopi, moray eels and giant sharks!

Registration is limited, so register early.

Wednesday, November 20, 2019

Stream 1a

Design & Engineering – Architectural Focus

Stream 2

Operations and Facilities Management

Stream 1b

Design & Engineering – Systems Focus

Continental Breakfast in the Trade Show Area

7:30 am – 8:15 am

SLCan Annual General Meeting

8:15 am – 8:30 am

Welcoming Remarks

8:30 am – 9:00 am

Keynote

Improving Community Well-Being Through Engagement

Ritika Singh, My Green Lab

Ritika Singh is the Green Labs Program Manager at My Green Lab, a non-profit dedicated to building a culture of sustainability through science. Ritika organizes outreach events, conducts assessment analysis, and provides support for lab sustainability efforts and initiatives. Ritika holds a Bachelor’s Degree in Biological Sciences from the University of California, Irvine (UCI). Prior to joining My Green Lab, Ritika worked as a researcher in a marine biology laboratory and as an outdoor educator with a focus on environmental and ecological sciences.

Description

Engaging scientists in sustainability efforts has long been proven to be an effective way of reducing the environmental impact of laboratories. More recently, these outreach activities have been shown to improve the health and well-being of the scientific community. Scientists who are engaged with Green Labs programs routinely report improved job satisfaction and a greater sense of community not only within their laboratory spaces but also within their campus. Additionally, by implementing actions to improve sustainability, scientists experience a healthier environment, with reduced exposure to hazardous materials, which leads to improved lab safety. Case studies from industry and academia will be presented to demonstrate the positive health and wellness benefits of engaging with researchers through Green Lab programs.

Within the bureaucracy of large institutions, individuals can often feel as if their personal impact is meaningless. By educating the scientific community and providing laboratories with specific, measurable goals, Green Lab programs empower individuals to make a change and grants them a sense of social responsibility for their actions and impacts.

9:00 am – 9:30 am

Keynote

Donadeo Innovation Centre for Engineering = Innovation + Design + Culture

Donna Clare, DIALOG

Donna Clare is an architect and principal at DIALOG, an interdisciplinary design practice with studios in Canada and the United States. Donna holds a Bachelor of Science in Honours Biochemistry from the University of Alberta and a Bachelor of Architecture from the University of Toronto School of Architecture. Since graduating she has practiced in California, British Columbia, Alberta and Ontario. Over the past 30 years, her portfolio of work covers a broad spectrum—arts & culture, education, healthcare, post-secondary, research, mixed-use, and devotional buildings.

Description

Universities have medieval roots that say everybody gets their own castle, and the castle has to have a little bit of everything in it. It has to have a grain storage facility, it has to have a place for the animals. It’s got to have all those things, and we at the university just replicate that. Every department gets the building and it has all mixed functionality. When you stop and think about it, it’s the absolute worst way to design and build your facilities.

The big bonus is this (Donadeo ICE) brings everybody together and all the potential things that would keep people apart – distance, space, others – go away.” David Lynch, Former Dean of Engineering, University of Alberta

The completion of the Donadeo Innovation Centre for Engineering enables a transformative change in administrative business and operational practices for the entire Faculty of Engineering at the University of Alberta. The Centre provides approximately 28,500 square meters of interdisciplinary office and collaborative space accommodating over 1,700 professors, graduate students administration and support staff for the Faculty of Engineering.

The construction of this facility frees up the equivalent area across four existing research and teaching facilities – the Markin/CNRL Natural Resources Engineering Facility, the Electrical and Computer Engineering Research Facility, the Engineering Teaching and Learning Centre and the Chemical Materials Engineering Building. These four buildings have the floor loading and building systems to support advanced research and teaching. The use of 27,500 square meters of space within these facilities for office and administrative functions does not fully leverage the infrastructure in place to support research and teaching functions. By moving these functions to a building designed for office functions, the research buildings can now be economically renovated to support expanded educational and research activities for the Faculty of Engineering at one third of the cost and a fraction of the time needed to build new research and teaching facilities. In addition, consolidating common departmental functions and space needs generates operational efficiencies that contribute to the financial sustainability of the Faculty.

Bringing together faculty members and students from across multiple engineering departments into a single building is bringing about a cultural shift, creating an atmosphere of even greater interdisciplinary collaboration in teaching, research and support. Faculty from many different areas are located close together so that they can all collaborate and interact across four major research areas of energy and the environment, nanotechnology, information and communications technology, and biomedical engineering. It also enables the Faculty to add another 50% to their graduate student population to move from 1,600 to 2,400 graduate students and to increase their undergraduate student enrolment – literally a 50% expansion in the Faculty of Engineering with the construction of a single new building.

The project seeks to be socially, economically and environmentally sustainable. The integrated approach to addressing the space needs of the Faculty of Engineering optimizes both the use of the available land and the use of existing facilities. It also provides much needed social and collaboration space missing from many of the older buildings on the campus especially the interconnected Chemical Materials Engineering Building. These informal spaces are essential for building the culture of the Faculty, supporting the wellbeing of students, staff and faculty and nurturing a new sense of community across departments.

9:30 am - 10:00 am

Refreshment Break in the Trade Show Area

10:00 am – 11:00 am

Concurrent Sessions

Stream 1a

Som Bose – Implementing an Allegorical Framework for Design, While Achieving Energy Efficiency in a Radioactive Isotope Production Facility

Som Bose, Architecture 49 Inc.

Som has 17 years of experience in numerous role settings within the design and construction industry. Som possesses specialization in Science and Technology projects through his work for US pharmaceuticals and institutional companies as well as US Federal Agencies during his time with Laboratory AE firm in the US. He has experience working on containment laboratories, Cleanroom for semiconductor manufacturing and radioactive Shielding laboratories for physical science research.

Prior to Architecture 49, Som was leading the Design-Build pre-construction services for Asia’s oldest contracting company SP Engineering and Construction in Mumbai-India. Currently, Som is the founding president of the AIA’s Canada chapter and a past board member of Sustainable Laboratories Canada. He is a member of (Architectural Institute of British Columbia) AIBC and holds an NCARB certificate and maintains professional licensure in the US, Canada, and India.

Som has presented in Conferences in India, US and Canada on Biosafety, Biosecurity, Laboratories, Sustainability, Construction and Architecture practices. Som completed his Master in Architecture from School of Architecture and Urban Planning at UW-Milwaukee. He holds an Executive MBA from Mumbai’s top B-School – SP Jain Institute for Management Research.

Zlatko Puljic, AME Group

Zlatko Puljic P.Eng., HBDP, CEM, LEED AP, Principal

Zlatko has over 20 years of experience in design and construction management for a wide range of facilities. Since joining AME in 2012, Zlatko quickly progressed to the role of Principal with the firm.

Zlatko specializes in high quality, cost-effective design methods and the principles of high-performance building design, energy efficiency, and life-cycle analysis to every project. Zlatko has extensive experience in the design of complex mechanical systems and plants.

Zlatko is registered as a Professional Engineer in British Columbia, Alberta, and Ontario, a Certified Energy Manager(CEM) and LEED Accredited Professional.

Description

The purpose of presentation is to showcase a responsive design approach supporting programmatic and functional requirement in achieving energy efficiency, while balancing competing needs for an allegorical framework in articulating architectural forms, building elements and relationship to each other.

Stream 2

The Paradox of Green

John Alberico, RWDI

John is one of our most experienced consultants, with a nearly thirty-year record of delivering high-performance buildings for residential developers; colleges and universities; healthcare; governments and public institutions; and public-private partnership projects. John is known for forming strong, highly functional links across project teams, enabling architects, engineers, planners and construction firms to deliver excellent, well-integrated results on time and on budget. In addition to his building performance work, John has extensive experience in the development of transportation infrastructure, including airports, roadways, bus rapid transit (BRTs) and light rail transit (LRTs).

Duncan Phillips, RWDI

Duncan is our Global Practice Leader for Building Performance, heading up our talented pool of building performance engineers and scientists as they develop climate-responsive design strategies for individual buildings and masterplans. Our clients benefit from Duncan’s ability to solve tough building physics problems by analyzing airflow and heat transfer phenomena. These capabilities have applications in ventilation strategies as well as renewable energy. Duncan is a critical player in our efforts to both diminish buildings’ contribution to climate change through passive and low-energy design and to design for future climate scenarios by increasing buildings’ resilience to extreme weather events.

Shayne Love, RWDI

Shayne brings his deep expertise in structural dynamics to both our damping-systems team and our acoustics, noise and vibration group. Our clients benefit in particular from Shayne’s ability to maximize the efficiency of supplementary damping systems by applying his nuanced understanding of sloshing dynamics and nonlinear dynamic systems. Whether he is devising structural mitigation strategies to limit footfall vibrations in a busy hospital or solving structural control challenges in an ambitious skyscraper, Shayne’s research background and international project experience combine to deliver successful outcomes for building projects.

Description

This case study driven session brings to light the consonance and dissonance found between many high-performance building objectives; ultimately highlighting the paradoxical challenge of green building design.

Stream 1b

HMR New Research Centre – Conversion of an Old Convent into a State-of-the-Art Research Centre

Pierre Luc Baril, Pageau Morel

Pierre Luc Baril is Vice-President and Principal of Pageau Morel, a consulting engineering firm specialized in the fields of mechanical and electrical engineering, energy efficiency and ecodesign. Throughout his career, he has made significant contributions to many institutional, healthcare facility and research centre projects, including laboratories.

Pierre-Luc holds a Bachelor’s Degree in Mechanical Engineering and a Graduate Diploma (DESS) in Management. Over the years, he has obtained several accreditations: LEED AP in 2007, HFDP in 2008 (ASHRAE Healthcare Facilities Design Professional), and CFPS in 2018 (NFPA Certified Fire Protection Specialist). Pierre-Luc is the founding chair of the Montreal Chapter of Sustainable Labs Canada (SLCan). He is also involved in Construction Specifications Canada (CSC) and gives a certificate course at Polytechnique Montréal.

Philippe Ashby, DMA Architectes

Philippe Ashby received a Master of Architecture from McGill University in 2008, having previously completed a Bachelor’s degree at the University of Waterloo. He has been a member of the Ordre des architectes du Québec since 2012. Prior to joining DMA, his varied work experience brought him to a number of firms across Canada where he contributed to several notable projects.

With DMA since 2009 and partner since 2014, Philippe Ashby has played a key role in several renovation and transformation projects always keeping the user experience at the heart of his priorities. In addition, he is very active in developing several areas of the firm’s practice including BIM, building envelope inspection and repairs as well as laboratory design.

Description

This presentation is to share the challenges associated with the conversion of an old convent building into a state-of-the-art research centre for a Montreal Hospital and to demonstrate how it was possible to repurpose the building while keeping the user experience and quality of the space as the main focus.

11:00 am – 12:00 pm

Concurrent Sessions

Stream 1a

Sustainability and Wellness in Research Facilities: Case Study of Georgia Cancer Center’s M. Bert Storey Research Building at Augusta University

Shrey Chandra, Architecture49

Shrey is a Project Manager and Senior Lab Designer with 12 years of international experience in planning and design of research and science facilities. He has executed and managed concept design, construction documentation, contract administration and all aspects of science projects. Shrey specializes in planning, conceptualization and design of new and existing facilities, including code research, equipment & material selection and implementing technical and code requirements. Shrey is a LEED accredited professional with a Master of Science in Architecture degree from Georgia Tech, Atlanta, and Bachelor of Architecture degree from Indian Institute of Technology, Roorkee, India.

Description

Completed in 2018, the new Georgia’s Cancer Center’s M. Bert Storey Research Building at Augusta University is an integrated research facility with both research and clinical care capabilities. This facility was envisioned to meet Augusta University’s goals to create a single, comprehensive cancer center to decrease operating/capital cost and improve patient care.

The $42.5 M (USD) expansion, added 80,562 gsf of labs, vivarium, and offices, and connected existing research and clinical building with an elevated office block. The project was designed to leverage existing circulation, amenities, and utilities, and create new shared amenities to avoid duplication and bring operational efficiencies. The sustainability goals of the project were based on Georgia Peach Green Building Certification. The purpose of the Georgia Peach Program is to rate and recognize buildings owned or managed by the state to optimize energy performance, promote the use of materials produced in Georgia, improve environmental quality in the state, protect the state’s natural resources and reduce the burden on the state’s water supply.

The presentation will focus on the correlation between sustainability and wellness in a research facility. The various design features of the project including daylight, transparency, safety, collaboration, flexibility, adaptability, accessibility, space sharing, etc. are related to the determinants of wellness such as air, water, comfort, light, fitness, nourishment and mind. The laboratory design was based on the functional and technical requirements of the process and equipment, and quality of design was based on the various factors include durability, adaptability, energy efficiency and safety. The presentation will also include a collaboration model that was adopted to enable participation between key stakeholder to successfully deliver the project.

Stream 2

Safely Retrofitting Existing Laboratory Exhaust Systems for VAV Operation, With Case Study of Simon Fraser University

Mary On, Integral Group

Mary is a project manager in Integral Group’s Vancouver office with over 15 years of experience in HVAC design and construction. Mary has a strong focus on lab projects including chemistry, forensics, and biosafety containment labs, and was the mechanical engineer of record for major lab projects such as the new RCMP Forensic Lab and the Stewart Blusson Quantum Matter Institute at the University of British Columbia. Mary is a Registered Professional Engineer in British Columbia and a certified Passive House Designer

Ryan Parker, CPP Wind Engineering

Dr. Ryan Parker is a project engineer with CPP Wind Engineering and specializes in wind engineering and experimental fluid mechanics, primarily as applied to modeling dispersion for laboratory exhaust systems. His expertise includes lab-based testing, field testing, and commissioning of VAV exhaust systems. He has helped multiple institutions design and implement safe and energy efficient, for both new projects and existing retrofits.

Description

There is often great energy savings potential associated with retrofitting existing constant volume laboratory exhaust systems in existing laboratories. However, there is always concern that such a retrofit will significantly impact the ongoing science in these existing laboratories. Often these labs are heavily used and any down time comes at an extreme premium. Therefore, there may be reluctance to consider the retrograde even if the energy savings potential is significant. The objective of this presentation is to describe the process involved in the upgrade of an existing CAV exhaust system by implementing a VAV exhaust system into an existing operating laboratory with minimal or no down time within the lab and showcase the energy savings of such upgrade. Two successful projects at Simon Fraser University and University of British Columbia will be used as examples.

Stream 1b

Optimizing Laboratory Central Plant Strategy

Diana Smith, DIALOG

Diana Smith is a highly motivated mechanical engineer. Having an analytical mind and a strong sense of ownership, Diana strives to complete the job in the best way possible. She loves being a part of projects that positively change the city she lives in and has a keen interest in sustainable design and working with other disciplines. Diana joined DIALOG in 2011 and has worked on a number of captivating projects, each with their own challenges and opportunities. Her technical expertise and community involvement won her the Consulting Engineers of Alberta Harold L Morrison Rising Young Professional award in 2019.

Grant Kidd, DIALOG

Grant has focused his extensive consulting experience on large institutional and commercial projects including health care and laboratory projects, post-secondary facilities, and airports. Grant is directly involved in project responsibilities from conceptual design through to construction and warranty periods. Grant is deeply involved with early stage building performance modelling, life-cycle costing and best practices, sustainability, mentoring and guidance, quality control, and commissioning. He pushes the envelope of sustainable design to incorporate integrated mechanical design concepts from Net Zero, Living Building, and AIA 2030 challenge philosophies to new laboratory designs.

Description

The goal of the proposed testing laboratory project was to create a patient focused “globally competitive, high quality, fully integrated, innovative, and sustainable laboratory system to enable patients and providers to achieve the best health care outcomes.” The laboratory would be a work place, a teaching and learning environment, and a research facility, designed for knowledge worker innovation and wellness. The ability to recruit and retain the best technologists, laboratory specialists and physicians, would be enhanced by a design that improves collaboration and worker wellness including mental, physical and social health.

The laboratories were central to the design since they are designed for high volume, high through-put analysis of patient tests. Laboratory functionality, adaptability, flexibility and safety were vital to the success of the project. The facility mechanical design had to be adaptable to the functional changes that would occur over the life of the facility including new and emerging diagnostic technologies. Resiliency was critical for this project and head end equipment had to have N+1 redundancy.

The heating and cooling plant strategy needed to balance heating and cooling energy throughout the seasons. The project location is in Edmonton, a heating dominated Climate 7 zone, however with the high equipment and receptacle load the laboratory space often required cooling year-round. A high number of air changes also results in fan power, air pre-heating, and cooling being the highest contributors to energy use instead of the envelope. Multiple heat recovery strategies were investigated and implemented, including harvesting heat rejected from laboratory freezers and process equipment.

The requirement for laboratory resiliency dictated life safety and standby power generation in excess of minimum code. This led to a decision to pursue natural gas generation instead of diesel-fueled standby generation. Mechanically, natural gas generation led to pursuit of a cogeneration plant to generate useful heat for the building and lower greenhouse gas generation compared to the utility. This led to further mechanical changes to use the heat rejected all year such as incorporation of an absorption chiller.

This presentation will show how the main mechanical heating and cooling design evolved significantly between initial schematic and the final design. We will describe how the project benefits when mechanical engineers are flexible in incorporating new strategies and equipment into their initial design. Discussions with the other disciplines, the owner’s facilities team, the client project manager, completing a life cycle analysis and adjusting for budget constraints all influenced the overall design.

12:00 pm – 1:00 pm

Lunch and Keynote

Program Overview & Update on Architectural & Engineering Initiatives for The Federal Science and Technology Infrastructure Initiative (FSTII)

Chris Gatt, Federal Science & Technology Infrastructure Initiative (FST)

Chris Gatt is responsible for the creation and leadership of Architecture and Engineering services for the delivery of FISTIIs new laboratory infrastructure across Canada. Chris has over 30 years experience which includes many years with Federal Government as well as vast private sector experience. As a licensed architect in the private sector Chris had a wide range of experience designing buildings including the Henderson Hospital Research Building and the Henderson Hospital Cancer Centre in Hamilton, ON. Chris delivered demand analysis/ cost estimate and prepared RFP for A&E services for the full scope of FSTII phase one projects

Kashyap Desai, Federal Science & Technology Infrastructure Initiative (FST)

Kashyap Desai B.Eng, P.Eng, Certified RETScreen Expert (CRE). Kashyap is responsible for delivering operational services in Architecture and Engineering for the Guidelines, Standards, Oversight of FISTII. In addition Kashyap is the key FISTII resource for Mechanical Engineering/ Sustainability. Kashyap has over 35 years experience mostly in private sector in Managing integrated Buildings Engineering Projects including numerous projects in the Science, Technology, Engineering and Research sector. Kashyap has also received various ASHRAE awards in recognition of his contribution to sustainability, innovation and energy efficiency. Projects managed/designed by Kashyap have been implemented in Canada, USA, Australia, India and Middle East

Description

The Government of Canada is committed to building a stronger, more collaborative federal science and technology ecosystem. FSTII will create a world-class, national network of federal laboratories to support evidence-based decision-making, collaboration with partners, and innovation in core program delivery, including regulatory responsibilities. This new approach to federal science and discovery will bring together federal scientists and science facilities across government to advance interdisciplinary research on Canadian science priorities.

Many of the individual projects will be running concurrently in multiple locations.

This initiative will have a integrated approach to Science/Technology which takes into account an effective design philosophy, approach and methodology.

The guiding principles will include Modern Design, Flexibility and Adaptability, Scientific Innovation, Functionality and Modernization, Collaboration, Environmental Sustainability, Universal Accessibility

1:00 pm – 2:00 pm

Concurrent Sessions

Stream 1a

Net-Zero Energy Mohawk College Joyce Centre for Partnership and Innovation: High-Performance Lab Supports High-Functioning People

Kevin Stelzer, ENFORM Archetects Inc.

Kevin is a founding principal of ENFORM Architects, a practice that specializes in ultra-energy-efficient design in educational, laboratory and retrofit building sectors. He has worked across Canada, the United States, the UAE and Asia. He studied architecture at the University of Waterloo and studied Building Science at the University of Toronto. He is a licensed architect and a Building Science Specialist. He has served on the CaGBC Energy & Engineering TAG, on the UN SBCI Task Force, volunteered for the WGBC and currently sits on the CaGBC Embodied Carbon Working Group. He was the recipient of the 2017 CaGBC Toronto Leadership Award.

Description

The Mohawk College Joyce Centre for Partnership and Innovation (Architects: McCallum Sather & B+H Architects, Principal-in-Charge: Kevin Stelzer) is the Fennell Campus new teaching and research engineering lab. It is a full net-zero energy performance facility, one of the largest in the country (96,000 ft2). It recently garnered CaGBC Zero Carbon Framwork certification and The 2019 Innovation in Architecture award from the RAIC.

This presentation will outline how the design team partnered with the College to make critical alignments between sustainability goals and academic goals. At the outset, the design team prepared an innovative benchmarking and energy budgeting analysis to establish early frameworks to ensure the net-zero energy performance target was achieved.

Stream 2

Carleton Academic Health Sciences Building – A New Way of Thinking of Smart Buildings

Stephan Riffault, Regulvar Canada Inc.

Stephan Riffault, P.Eng. is a mechanical engineer with over 20 years’ experience in the HVAC and automation industry. He has worked both as a consultant and contractor and has assumed many roles including design, project management and sales. He has been involved with Regulvar’s multiple laboratory controls projects for over 12 years.

Daniel Redmond, Carleton University

Daniel Redmond, P.Eng. has extensive experience in building systems. Prior to joining Carleton University, Dan was a Senior Design Consultant for a large Mechanical Design firm. Dan has also been a commissioning agent for large scale international projects. He is currently the president of the Ottawa Valley Chapter of ASHRAE

Description

The new Academic Health Science Building is a leading edge construction that uses the latest technology to operate better while being more environmentally friendly and providing an optimal environment for its occupants.

The Academic Health Sciences Building posed several technical and operations challenges as it houses several types of spaces including large laboratories with fume hoods, live animal are areas, teaching areas and offices and meeting spaces. In order to ensure all the occupants well-being while remaining efficient and energy wise, several technologies and systems had to be streamlined and harmonised to work as single unit.

The process started early in the design phase: A collaborative design strategy was used where all key stakeholders were brought together to identify their needs and concerns to create an ideal environment from the start rather than dealing with occupant needs as an afterthought. The team included the architects, two M&E design firms, animal care specialists, user group representatives, Carleton project management and operational staff and Regulvar. As a team, this group was able to define user needs and select innovative solution that would meet these requirements within the project’s timeframe and budget.

The technical challenges in deploying the automation systems in Academic Health Sciences was to put together numerous complex components while making everything simpler and more intuitive for the occupants to use. This building in fact, has more sensors, more networks, advanced lighting control systems, extensive sub metering, state of the art lab controls, automatic shade controls and complex HVAC strategies but is put together to run itself with minimal intervention and can be easily operated from a single interface with very simple interventions.

Each occupant’s space can be tailored to maintain the temperature and lighting levels they want while optimizing energy usage. Also the environment is more closely monitored (Humidity, CO2, occupancy) in order to provide conditions that are optimal for everyone’s well-being.

Not only human well-being had to be considered for this building, animal care areas required special consideration that included lighting controls for various colours and levels on an irregular day cycle. The ventilation for animal care was also harmonized to the lighting, so ventilation rates will follow occupancy requirements automatically as well as respond to gas detection in key areas. This was brought to an automated interface that lab operators can easily use to monitor of change conditions.

The well-being and long term engagement in this building is ensured by the departments of Engineering and Architecture. A group of graduate students is using the Academic Building as an ongoing research project to optimize control strategies in the building. The innovative approaches they use make the building operate more efficiently and more in line with occupant behavior, giving people what they actually need as space conditions rather than what has been dictated by conventional guidelines.

The tools and technologies provided are permitting the University with staff and Grad students to evolve the operations within the building for better energy management as well as occupant well-being.

Stream 1b

Sustainable Transformation – Farquharson Life Sciences Building Case Study, York University

Patrick Saavedra, York University, Director, Planning, Architecture, & Renewal Projects

Patrick oversees approximately 200 projects a year and several large capital projects. Patrick has a Bachelor of Architectural Science from Ryerson University, a Masters of Architecture and Masters of Urban Planning both from the University of Michigan, and has completed studies at University of Copenhagen. He has 25 years’ professional experience as an architect, a planner and an educator. Patrick currently teaches foreign trained architects at Ryerson University in a post-professional program. He has been a guest critic at several architectural schools in the US and Canada and is involved in several advisory roles as a member of The City of Toronto’s Public Art Commission, the City of Mississauga’s Urban Design Review Panel.

Ron Ogada, York University, Manager Renovations

Ron is the Manager Renovations at York University where he oversees approximately 200 projects a year and is involved in the University’s capital projects. Ron has a Bachelor of Science in Civil Engineering from the University of Toronto. He has 30 years’ professional experience as an Engineer, Building Science Specialist and Project Manager. Ron recently became a Certified Passive House Designer.

Jay Levine, NXL Architects, Founding Principal

Jay is the founding principal of NXL Architects, a Toronto design firm specialized in Science and Technology facilities. A graduate of University of Waterloo, for over thirty years Jay has focused on the design of scientific research and clean environment spaces, working with clients such as York University, Carleton University, University Health Network (UHN), Eurofins Alphora Research Inc.and Therapure Biopharma. As an authority on the design of complex, controlled-environment facilities, Jay has spoken at the Tradeline Conference on Research Facilities, SLCAN Annual Workshop, Toronto Biotechnology Initiative, Toronto Research Symposium, and the International Society of Pharmaceutical Engineers.

Sherif Saleb, NXL Architects, Project Director

Sherif joined NXL in 2010. Sherif is a highly experienced project manager, skilled at managing large-scale, complex projects in the healthcare, residential and commercial sectors for both domestic and international clients. Sherif’s experience managing projects over $100M, his strength with design solutions and technical coordination, along with his education in Architecture and Project Management make him a valuable member of NXL’s team.

Description